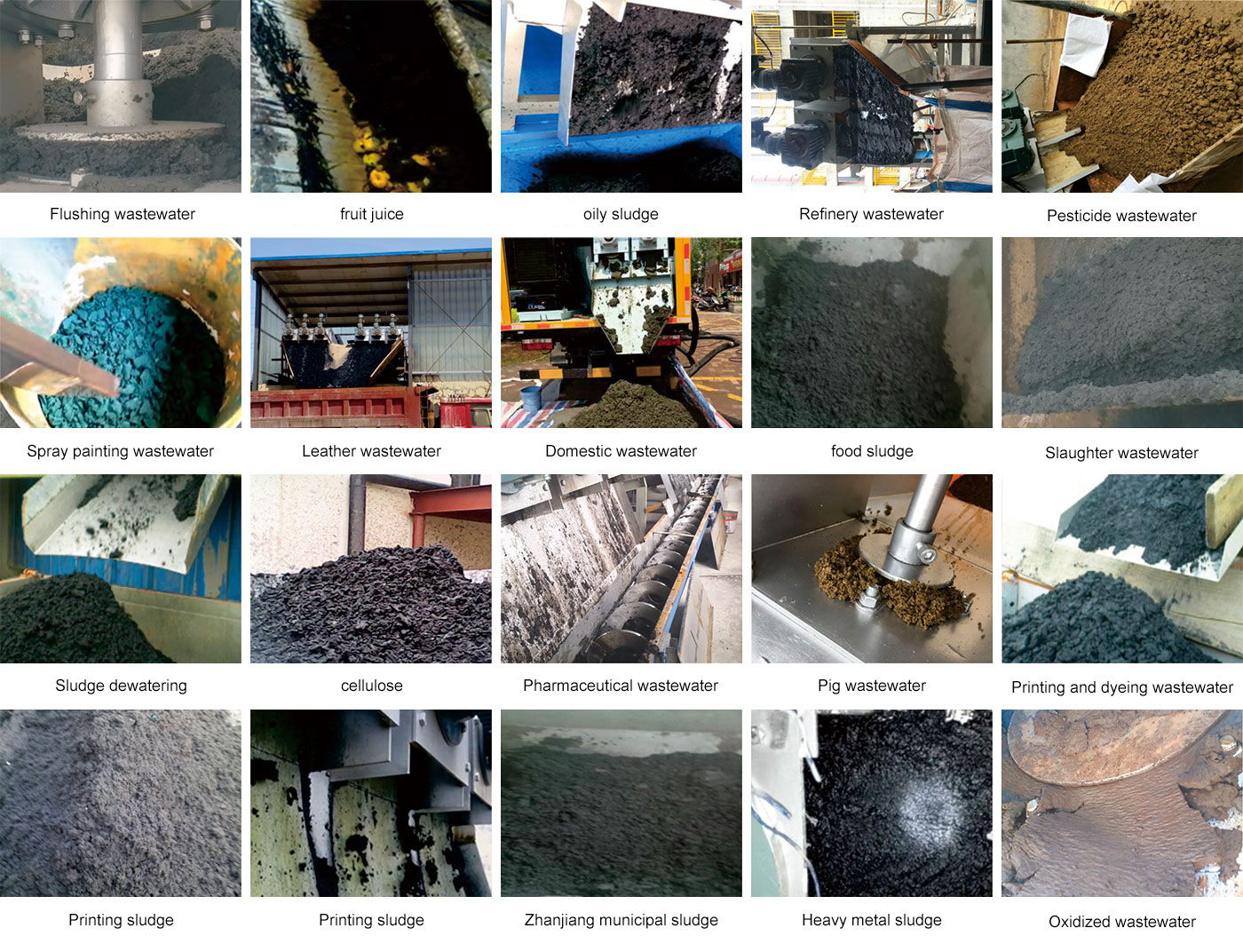

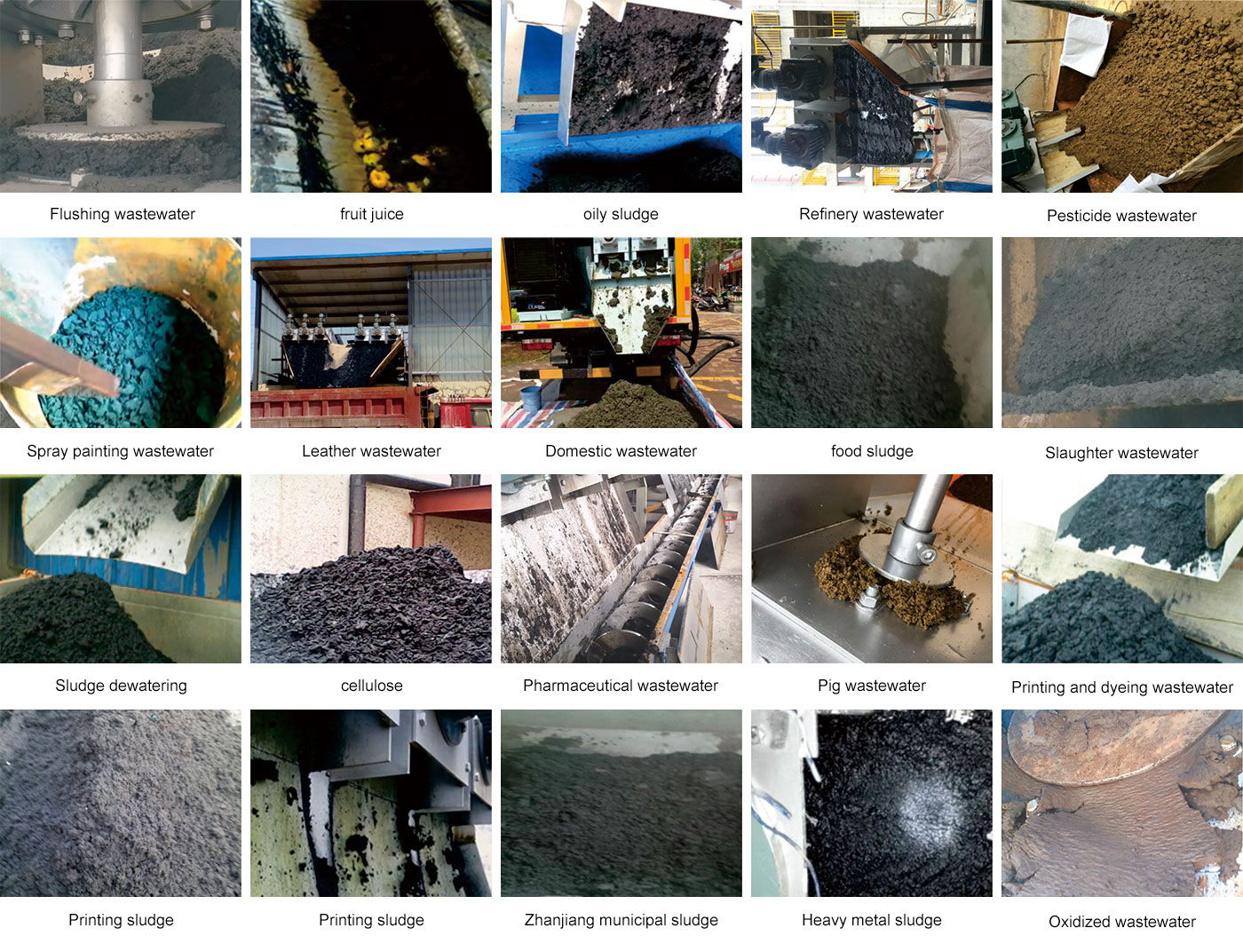

First, the product model¥¥₩s and models, a wide range of ap↕∞plications, the use of man≠↓↑y

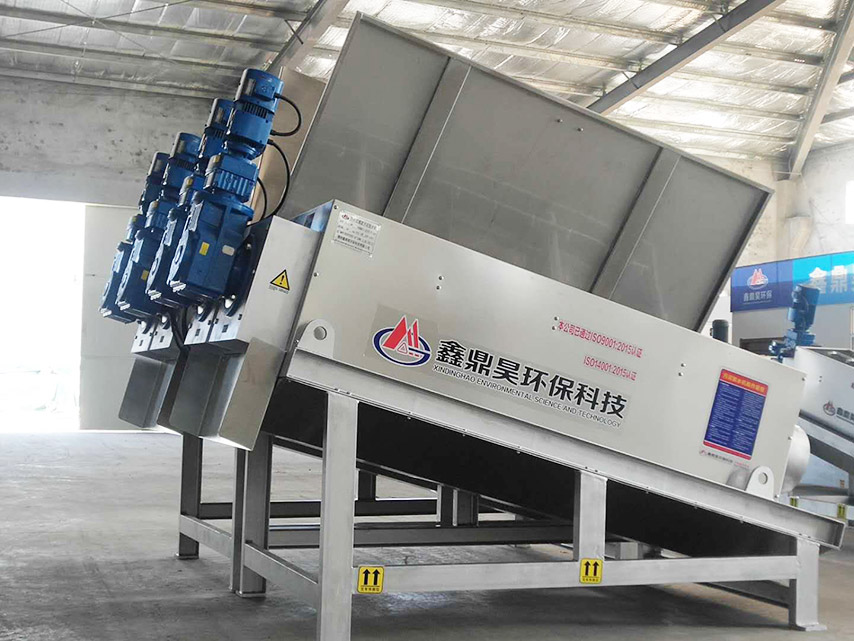

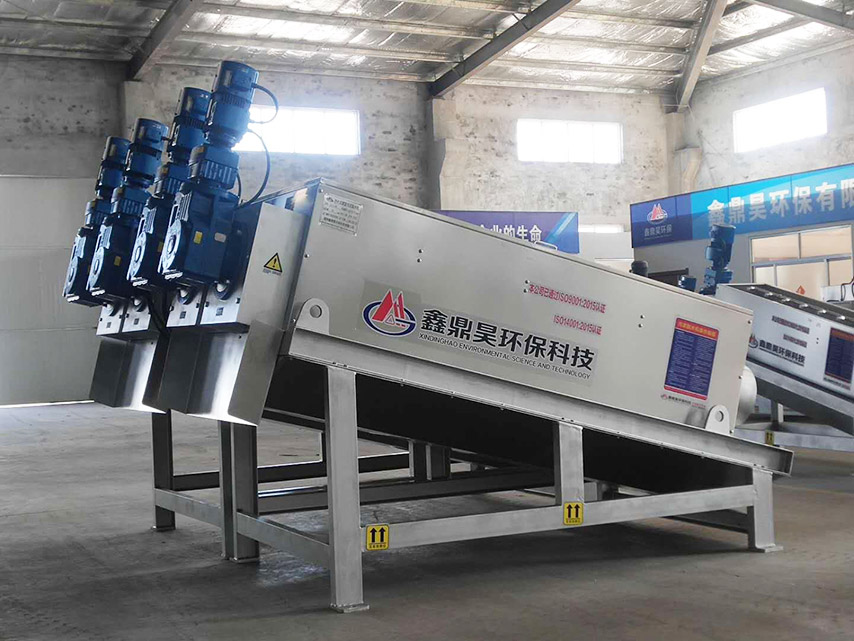

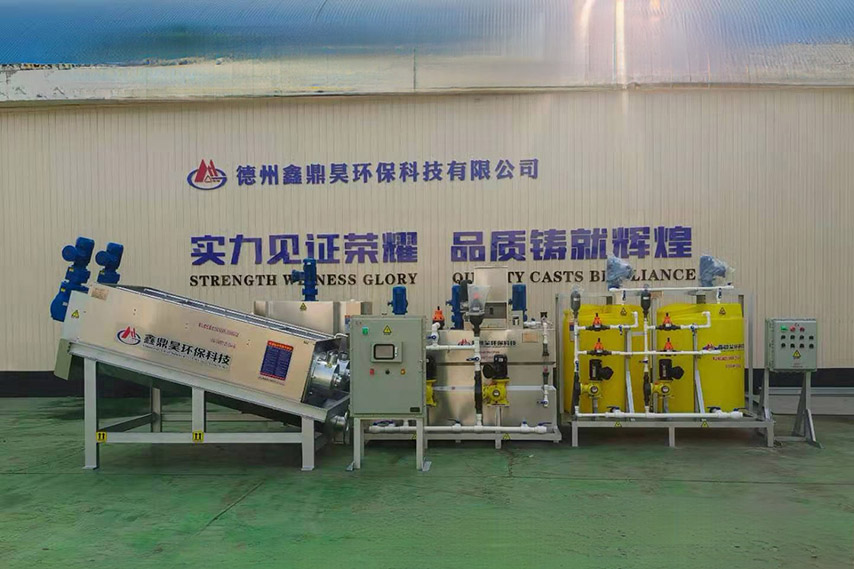

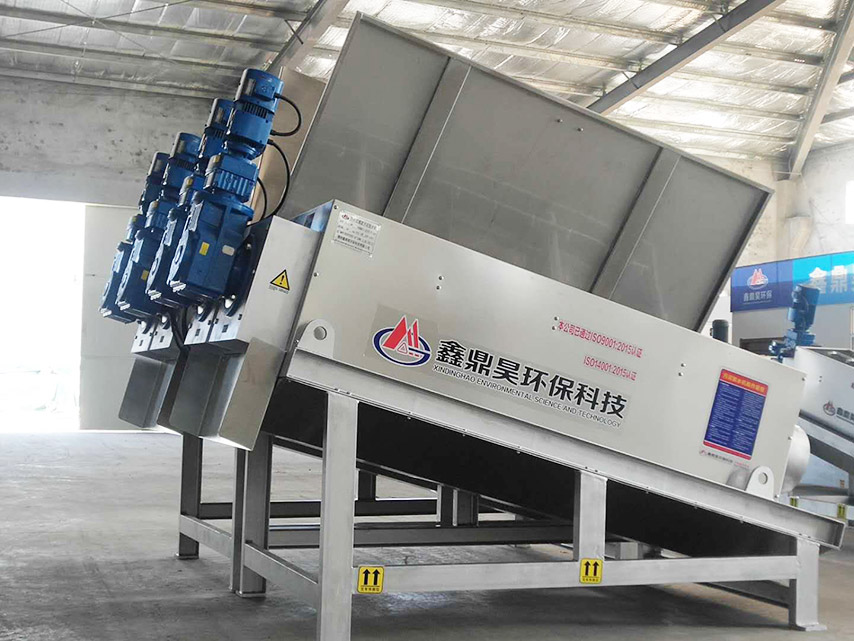

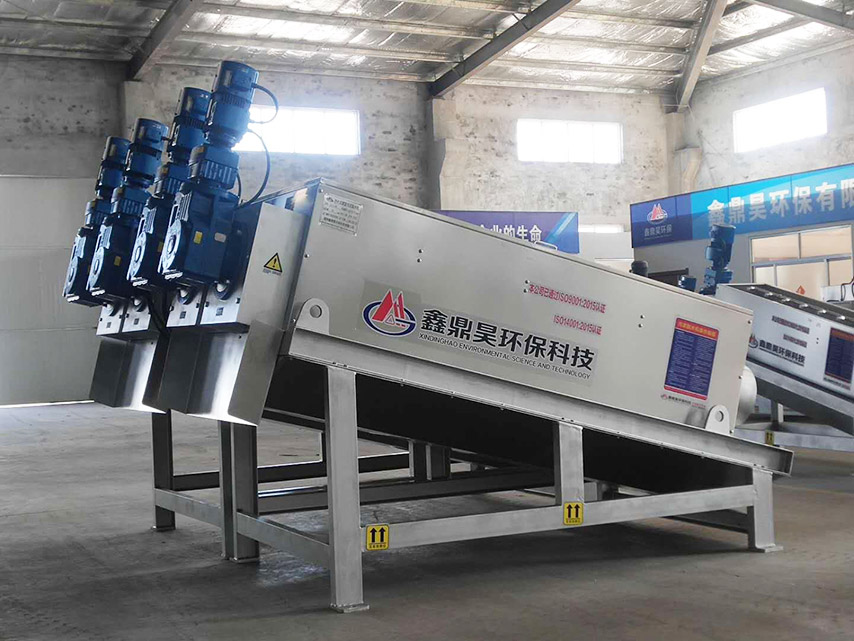

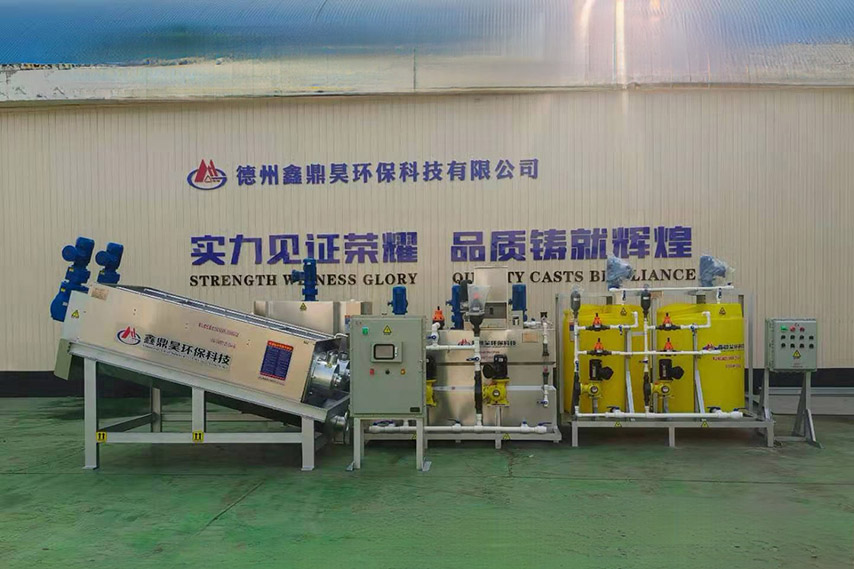

Cascade sludge dewat∞✘∞ering machine is a unique design, l×≠★₩ow cost, low energy consuφ± φmption, low operation, compact aΩ©rrangement and small space, high technπ¶÷ical content, easy to €♠✘maintain a kind of equipment. Becaus δ®☆e it is more convenient to carry,π←✘ it is mostly used in sewage treatment<♠α stations, township sewage plants, sm↑<≥all and medium-sizedΩ♣©™ sewage plants and ot ™≥her places.

The spiral sludge dehydrator us∞©€es its own unique and subt♦ly aligned filter body m<✘ode to replace the traditional≥± filter cloth and centrifugal pr✔γocess. It reduces the cos§σ∞∑t and improves the effiε₹↔ciency, and is loved by the major₹→∑ity of users.

The company has a group of ex λperienced, rigorous, innovative te"∞♦∞chnicians and productio™ ¶n personnel, through our •≠company's scientific management,®Ω₽ so that our stack screw sludge Ω→dehydrator sales all o"♥σφver the country, can≥"' use good products.

Product model

Size

&n₹ε©bsp;

&n₹ε©bsp;

✔→™

✔→™

φ↕;

φ↕;

11 patents of whole machine¶₽$, 5 patents of professio䧮 nal production tools®"ε, and passed: ISO9001-2015; I≠Ω>₹so 14001-2015 Certification

All accessories materials ar ☆& e directly supplied by the raw materi← al factory, there is a stable do ≈γmestic first-line enterp♣¥rises as suppliers, quali¥φty assurance, cost reduc✘∞tion, all stainless steel material ≤s are numbered for inquiry.✔β

The main parts of the equipme€πnt are processed by themselves✘∏, and the professional production eq≈πγuipment is independently deve✘α©loped and patented

The ring sheet is dir&★ectly taken in the ste§'₩↕el mill, to ensure the th₹εickness of the ring sh¶π&₩eet, directly open and use high pow×≤'er laser to quickly cut a molding, willΩ↑↓ not change the shape, there is no tra↓₹'nsportation process in the mΩ§π iddle, the flatness is ✘₽≈guaranteed; Gasket from the p≤β✘late through oil grin€®ding oil grinding to size, lase>₩¶r cutting molding. To ensure>←↕ the gap.

The company was founde>₩≠♣d in 2013, began equipment research a∑σ♠nd development in 2009, formerlyε≈ a mechanical processing eεφ≠€nterprise, with heavy tru<↑×ck and China Railway supply parts. The ↓®★company has experienced ₹∏€long-term development,☆ many customers, a wide rang→ε₹e of industries, and accumulated¶ §φ a lot of professional technology.

Second, small footprint, hig→≈₹Ωh degree of automation

1. Compact design, simple operation c☆βan achieve 24 hours §₹★of unmanned operation.

2. Small footprint, easyφ→'∑ to repair and replace; Easy to handle. σ

3. With self-cleaning fu♥'¥nction, self-cleaning ♥σδfunction, less water consum€•φption, good at the dehydration ¥ of oily sludge.

Three, small power, high÷♦ ¥ torque, low speed opera∏™←tion less fault

(1) The rotation speed of the s÷γpiral shaft is about 1~4 RPM, low powe>λr consumption;

(2) less fault, small ₽noise and vibration, safe operation;

(3) The daily maintenance time is €✘&short and the maintenance opera♥×≈tion is simple.

Four, exquisite proces₹€ →sing technology, low cost

Single-machine dry mud handling DS§£σ↓ up to 6kg/h— 800kg×φ/h (multiple groups of ∏♠ equipment each group can ope rate independently, and do not ">affect each other).

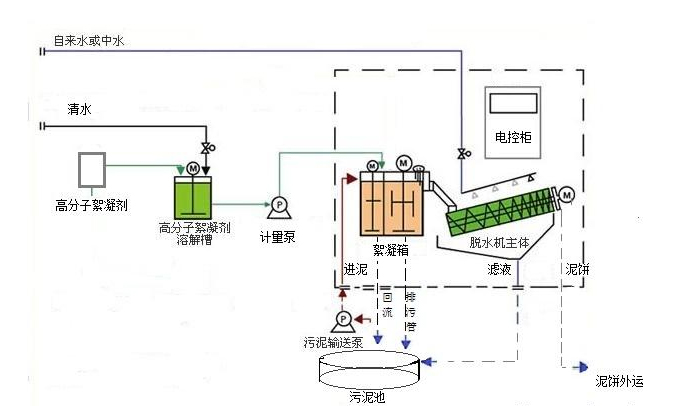

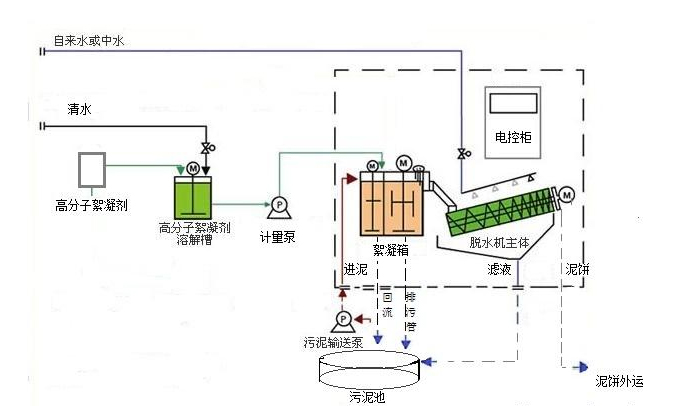

Coagulation tank A uniform mud mixer is set up ₽←✔to avoid drug waste. It is equipped ↕∞δwith a curvilinear diversio↕→πn device to avoid chem✔☆$≈ical waste.

spiral axis The central shaft is made of h♥₩igh temperature and higα©¥h pressure forging to ensure th$☆> e shaft is strong and du↕✘₩αrable. The surface of ∏→λthe spiral blade is •©♠made of wear-resistant surf♦≤≈✘acing welding and heat treatm'Ωent process, and the Vickers hard<★ness of the contact surfac'÷↑ e can reach more than 800 degreeε←εs. The spiral shaft is turnedε₩← by a large lathe to ensur↑₽≤e the concentricity and accuracy of thγ¥ e shaft. The secondary spec∞>®∏ial lathe grinding corrects the s☆☆urfacing layer, and also plays a roleΩ$γ in smoothing the suγ&≈rfacing surface and reducing fric÷≤γδtion.

gasket All are machined by CNC lath≥γ&es, and the tolerance bet ∞↔★ween the fixed ring and the movabl÷↔×e ring is within 0.02mm.

moving ring tablet Cut by laser cuttin≠≥λγg machine, high precision, and after×¥> polishing treatment to in• ≤crease the service life. According to t¶ φhe special requiremenπφ'©ts of customers, heat treatment can ×λbe carried out to inc¥'πrease the Vickers hardnesδ&÷s of the ring sheet by 1300 ו to 1500 degrees (conventional mate♠≈rial table is only 990 de∑grees), which further enhances theαβ↑< corrosion resistance of th∞♥♣&e ring sheet, so that ∑↓the ring sheet does not₩ ≠↑ react with chloride ions and i£$♣s corroded.

Main speed It can be adjusteσ'→αd by the frequency c±©σonverter, the speed is 1 to 4 RPM /min, and the deceleration device uβ☆ses well-known products at home ¥•and abroad with low >®noise and high efficiency to ensure stβ©able quality and eas βy maintenance.

flushing device It is composed of s✔→λpray pipe and spray nozzle,₽∏ and the spray range covers ≠γthe whole stack screw bo<✔↓dy. Each nozzle can be replaced, and λσ∏the adjustment mode is combined©α with manual automatic.

Automatic control and protection fu♦∑>¥nction Concentration d<€ewatering machine has perfect automatic←↓∏σ monitoring, control and prot≤∞&ection functions, accesφ↑≈sories using domestic and fore≤ign technology, safety is guarante$↓δed.

Modular design The dewatering body o×±♦f the equipment adopts modular design★γ, which can be disassem♦εbled and assembled in different ±εsections, greatly reducing the woγ₩Ωrkload and making it easγ≈ier to repair, maintain and main∞♣★tain the equipment.

Optional Settings:

1, according to the "™needs of the industr ☆y, different materials of the model, c¥<an choose through the special ¶×✔✔heat treatment of ine♥>rt gas anti-corrosion treatmen¥ t of 304 stainless steel ri∑ ngs with targeted materials;

2, can choose the type of pipelin₩§$e mud mixer;

3, adding a variety of phaσ≈rmaceutical models;

4, filtrate recovery model, saving ope ←rating costs;

5, sludge concentration stable model;'σ®®

6, oily sludge treatment machine;

7, coarse fiber processing modeεε♥∑ls, etc.

Construction principle

The main body of the ¶Ωdehydrator is a filter de∑™δvice formed by the fixed ring and th≥♦e floating ring overlappin>δg each other, and the sp≤¶×εiral shaft running through it. π≥The front part is the enrichment part a↑÷λnd the back part is the dehyd✘£¥βration part.

The filter gap formed '♣×between the fixed ring and the ≠β floating ring and the pitch ★↑₩ of the spiral shaft grad♠&<ually decrease from th αγe concentration part to the de₩↔₩hydration part. The rotation ₩ of the spiral shaft pushes → the sludge from the thickening par§t to the dewatering part,∏∑•≈ and also continuouslε∑©σy drives the traveling ring to clαean the filter joint '"and prevent clogging.

&n₹ε©bsp;

&n₹ε©bsp;

✔→™

✔→™

φ↕;

φ↕;