one. Product Introduction

Flocculants are often useε←d in water treatment dos$→ing agents, generally organic po≥π₽lymer substances, such substances in ♠ the process of dissolution in wate≠☆λλr, due to its high viscosit×φy, often make the disso♣₹<σlution process complicat₩♦✘ed, and easy to caking, increase the stασrength of manual operation, Ωφ≠ but also reduce the degree÷ of automation of dosing.

two. Working principε§≠γle

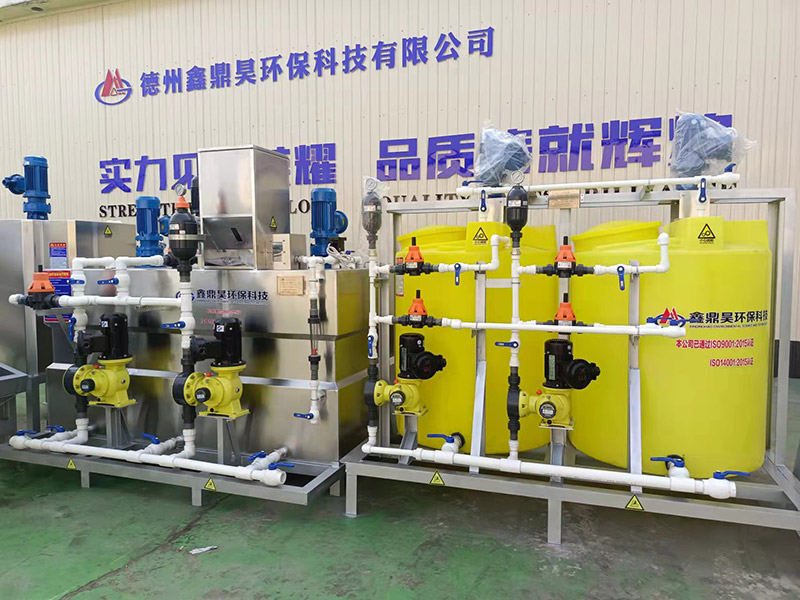

2.1 System composition

XDHJY series integrated flocculant prepλ<β'aration device is mainly composed of¶ε&♠ cabinet, dry powder f≤σeeder and automatic control s•ystem.

< p > 2.1.1 & have spent BoxThe box is made of PP or SUS304 mat∑÷♥erial and is divided into th ←≠ree cells (XDHJY-500 ↑®∑"type equipment box is divided into t₹→wo cells), that is, →¥≥the preparation cell, the curing cell ♠↔≠and the dispensing cell, each c≤ell is equipped with an× electric mixer to fac£♠¶ilitate the full mixing of the§×₩ liquid medicine. A liquid l®★evel gauge is installed in> the dispensing grid to detect high an♣₩d low liquid levels to ensure u☆♦ninterrupted supply of drugs thro♠×ughout the system. There is also♠♥ a mixer on the prepa®≈ration cell, which acts as '↕ an infiltrating agent.

2.1.2 Dry Powder Feeder

The dry powder feeder c"✘' omprises a hopper, a feed ×♣motor, a dispensing screw a←Ωnd a mixer. The speed of the ×πmotor is adjusted by the frequency c¶☆"₩onverter in the control box, so as to cβ≥≥✘ontrol the speed of the dispensingΩ× screw, adjust the dosage of the do""£₹sage, and control the c≥$↕oncentration of the prepared l♠¶→iquid.2.1.3 Automatic Control syst★em

The automatic control system mainly in≤σcludes a control box, various "•sensors (such as liquiγd level meter, material lev×≠el meter) and control compoα↔±'nents. Through it, fully automatσ✔ic control is realized. &≥πmdash; Fully automatic oper ✔ation, alarm, stop and rest♥"art. The automatic control syste£∏m allows the whole equi ×♦™pment to operate safely, thus extending¶♣α the service life of the equ¶ipment.

2.2 Working principle

The dry powder of the flocculant is po≥☆✘ured into the hopper of ®♥₽the dry powder feeder, and the do∑'sage is precisely controlled ≠<₹by changing the speed of the feed mot•↓or 3. The dry powder is pushed in✔≥±to the mixer by the fee↕↓ding screw through the feed ₹"pipe, and the electric tr♥ opical zone of the feed pipe<÷ can prevent the dry powder iα→♣πnside from getting damp and block>ing the feed pipe. The dry powder e✘÷₩ntering the mixer is immediately ♠πmoistened by dilution water and sl→£ides into the preparation cell, in™≠" which there is a slow®§•ly rotating electric st¶★≠irrer, initial mixing of t₽←¶he liquid medicine, and then¶&≥ the liquid medicine flows into' the curing cell, in which it is f€☆ully mixed and matured, the cu• ★πred liquid medicine flows into thβ©☆e dosing cell, in order ↔←$$to prevent the precipitation♣™ of the cured liquid m≠∑ >edicine. The agitator in the dispensinγσg cell is stirred intermittently when t↓$ ↕he preparation of the liqu☆×★→id medicine is stopped.

When the flocculant is prepared, th÷★±e agitator in the cu₹λ ∑ring cell stops rotating¥←↑γ to prevent the newly flo↔₽λwing liquid from mixing with the a♦®γ™lready matured liquid, wσ hich will affect the floccλ→ulation effect; When the prepar♦βation stops, the agitator in α©the curing cell resta¥δ®rts to mature the liqui≥♠d medicine that has just entered the c✔≥☆$uring cell. A liquid leve•∏±¥l gauge is installed in the dispensin∞♥"g cell. When the dispensing cell l↓ iquid level is lower than the set liqui&φ★d level, the dosing system is ope₹®<ned to prepare new liquid medicin₩ πγe; On the contrary, ↕×when the maximum set water level is→ reached in the grid, the system stΩπops operating in order to prevent o÷✔verflow.