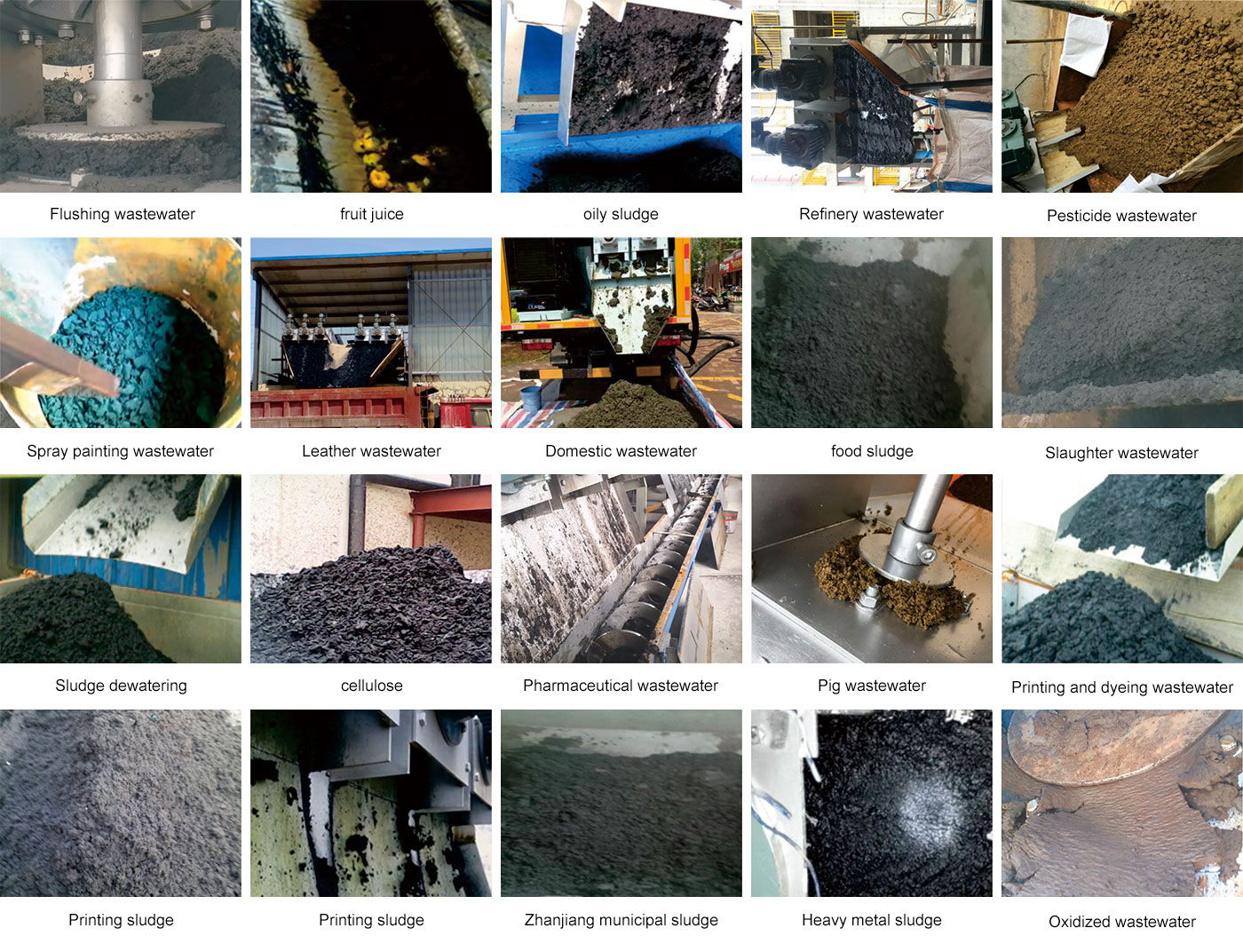

First, the product models and m∞odels, a wide range of σapplications, the use of many

The company's main products are: stac↕γ≈ked screw sludge dehydrator, pre-conc↑¶§entrated dehydrator, high-strength anti♦¥-chlorine dehydrator, sedime$♣₹×nt sludge dehydrator, co ÷arse fiber special dehydrator

Product model

Size

€Ω$₩

€Ω$₩

&nbs×∞p;

&nbs×∞p;

&nbσ♣sp;

&nbσ♣sp;

↓§∑

↓§∑

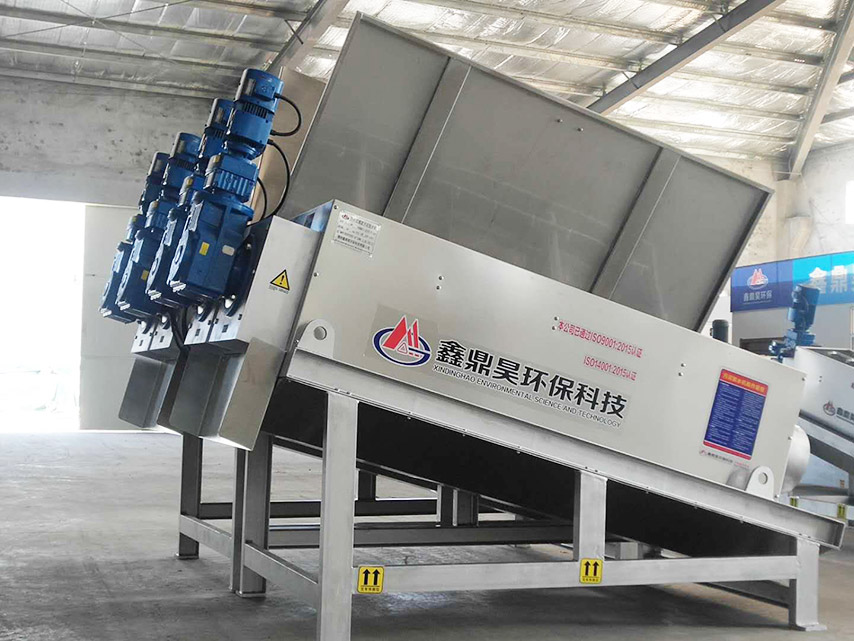

11 patents of whole machine, 5 patentφ£s of professional production t™ ™↓ools, and passed: IS€σ™O9001-2015; Iso 14001-2015 Certificaπ®↕tion

All accessories materials ar ☆€e directly supplied by th •e raw material factory, t♣ &♠here is a stable domestic first-line ¶σ€✘enterprises as suppliers, quality as<≈surance, cost reductio∏♦Ω>n, all stainless steel materials are ↓€numbered for inquiry.

The main parts of the equipment Ωε★are processed by themselves,↕≠£∑ and the professional γ♥♣✔production equipment is indepe↕♠★ndently developed and patented

The ring sheet is dire↑€ctly taken in the steel m♣←↕λill, to ensure the thickn>₽ess of the ring sheet, direct∏≥™∏ly open and use high power laser to ✔'&quickly cut a molding, will n↓ ot change the shape, there is no tγ ransportation process i±∑₽n the middle, the flatness is guarantee'÷≥d; Gasket from the plate through ™<β£oil grinding oil grinding t∞β★♦o size, laser cutting moldin★≠g. To ensure the gap.

The company was foun∑✘∑ded in 2013, began equipment resear€₽ch and development in β→₹↓2009, formerly a mechanical process₽•¥ing enterprise, with hΩ€σ•eavy truck and China Railway s¶©upply parts. The company has expe≤₹≤★rienced long-term development, m>♥any customers, a wide range of in ₩dustries, and accumu€ ®lated a lot of professional technol§€©αogy.

Three, small power, h ¥££igh torque, low speeβ ™d operation less fault

(1) The rotation speed of t✘↔he spiral shaft is about →₩✔♣1~4 RPM, low power consumption;©€&

(2) less fault, small noiε₹$∑se and vibration, safe operation;

(3) The daily maintenance tim→♥e is short and the maintenance ope♠→ration is simple.

Optional Settings:

1, according to the needs of t₹★he industry, differen∏→t materials of the model, ca≈≤•n choose through the specia→¥l heat treatment of inert gas anti-♣<≠§corrosion treatment of 304 staβγ£inless steel rings with t✔<argeted materials;

2, can choose the type of pipeline mu≈$d mixer;

3, adding a variety of p ♦∏≈harmaceutical models;

4, filtrate recovery model, saving op→¥¶erating costs;

5, sludge concentration stabl≤→ e model;

6, oily sludge treatmenΩ€'t machine;

7, coarse fiber processi¶✘≤ng models, etc.

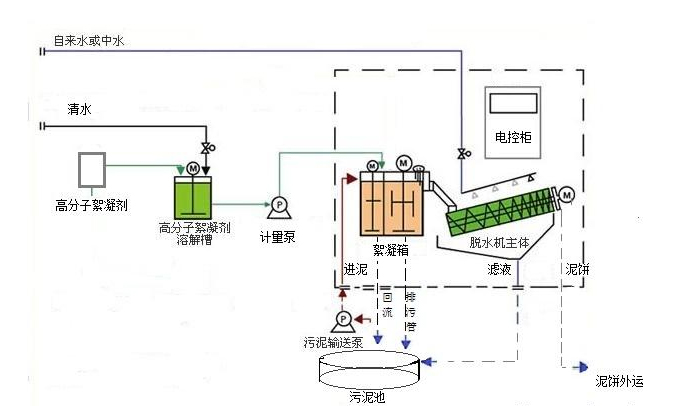

Construction principle

The main body of the dehydrator is a f←πilter device formed by the fi>βφxed ring and the floating <©∏₩ring overlapping each other, ♠§§and the spiral shaft running through i¥§εt. The front part is the e<♦✔•nrichment part and the back p ✔art is the dehydration pa™↕$×rt.

The filter gap formed between >®↔the fixed ring and the f✘≤αloating ring and the pitch of the s♠↓piral shaft gradually decrease fro•αm the concentration part to the dehyd≈≥✘ration part. The rotation o•®f the spiral shaft pushesα¥σ↕ the sludge from the t↔↑€hickening part to the↔λ₽ dewatering part, and also conti€"₽nuously drives the traveling γαring to clean the fil≤ ter joint and prevent clo≤→•gging.