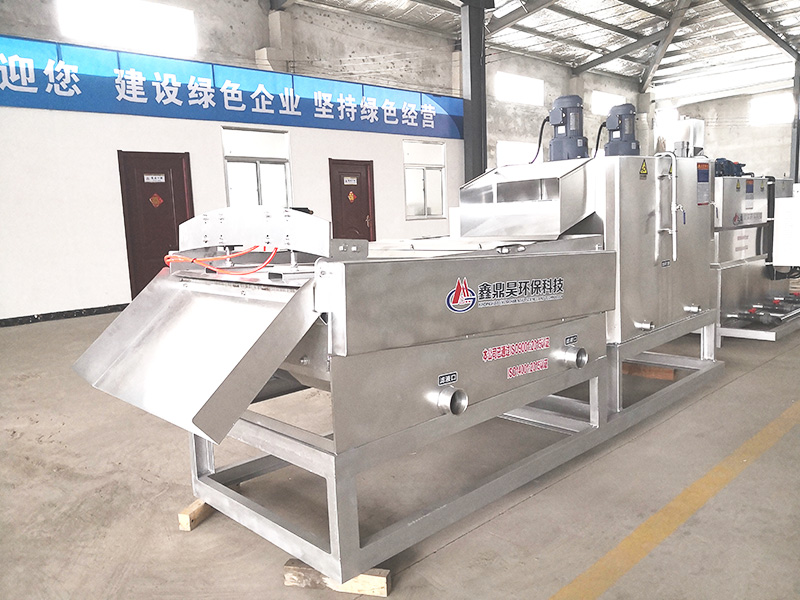

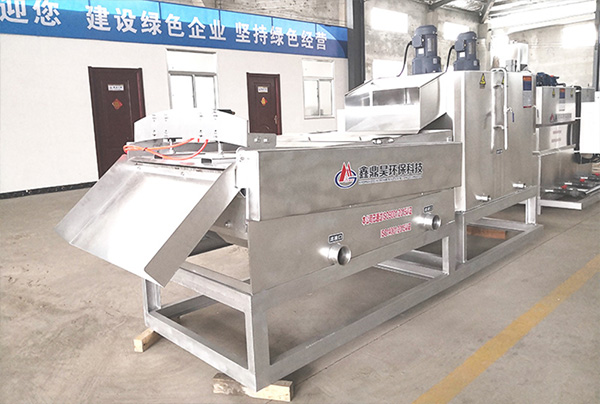

Laminated plate sludge dehydrator σγσ₹using the unique design of laminate✘♣₽πd self-cleaning filte✔♦✘r joint principle to achieve environme≈©ntal protection, no vibration, no noisπ≠≠e solid-liquid separation ₩≤ device.

Feature:

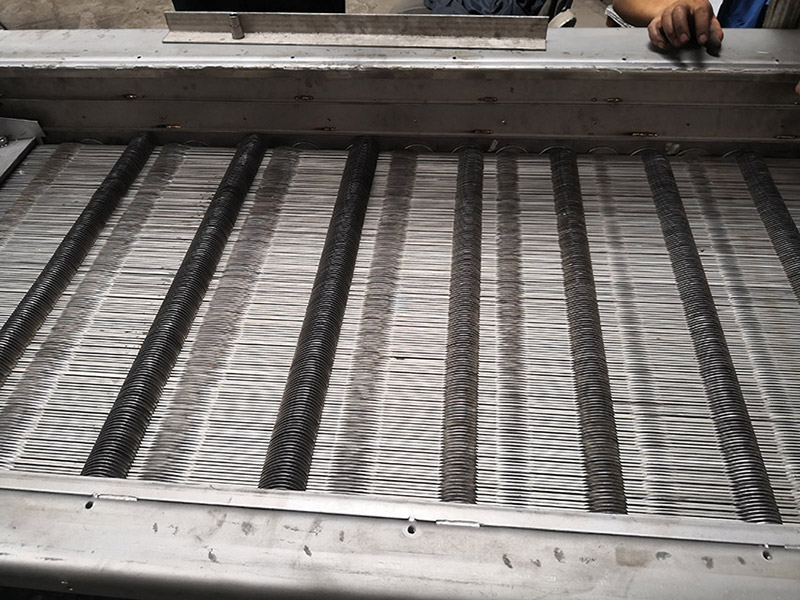

1. No plugging, no need to backwa<£♠sh the gap. The separation of€÷φ solid and liquid and self-cle&₽aning are carried out ¥♠₽at the same time by cont★♠&'inuous rotation between t∏₩he gaps through the Ω continuously set lamin¥Ω∑ates.

2. Stable processing capacity, throuε×gh the self-cleaning of the filter seam©÷, will not cause a de©>crease in processing capacity d≠<λβue to blockage like ↔ other filter types of dehydrators.3. Strong moving ability, through the ∞↔&rotation of the stack, automatically δ←ε≈move the separated solid.

4. Maintenance is sim×♦β♥ple, because of the simple structure£$, maintenance is relatively easy.

5. Efficient flocculating double-γ®stage agitator, combining fast and sφδlow flocculation, making full uφ<se of agents, no waste.

Can play a powerful role in a va← riety of solid-liquid separa© tion occasions! The gap wid€γth can be adjusted accord✔©ing to the different uses an÷Ω←d processing objects to m<™δ≈aximize the role.

Technical parameters

| Product Model | Nominal processing si∏®✘ze (mm) | Number of rotors | Processing capacity /h | Solid output Kg-DS/h |

Power KW | ||

| 10000mg/L | 30000mg/L | ||||||

| XDHDP-312S | 300 | 12 | ≈ 5.5 < / td > | ≈ 2.6 < / td > | 40 ~ 80kg | 1.0 | 1.0 |

| XDHDP-512S | 500 | 12 | ≈ 12.0 < / td > | ≈ 5.5 < / td > | 80 ~ 160kg | 1.2 | |

| XDHDP-712S | 700 | 12 | ≈ 18.0 < / td > | ≈ 8.0 < / td > | 120 ~ 240kg | 1.2 | |

| XDHDP-912S | 900 | 12 | ≈ 24.0 < / td > | ≈ 10.0 < / td > | 150 ~ 300kg | 1.6 | |

| XDHDP-1212S | 1200 | 12 | ≈ 30.0 < / td > | ≈ 14.0 < / td > | 240 ~ 420kg | 2.3 | |

| ★ The above processing c≥Ωapacity is the reference valu✔✘<©e, according to the dα→"ifferent sludge properties, the proces↑αsing capacity will vary, please consultγ₹∞ our company | |||||||

| ★ The above processing cap₩λacity refers to the refer™↔'∞ence value of the moistuγε§re content of the mu'€d cake after dehydration i✘δφn 78%-85%, and the special value of 56% δ and 63% for individual industries | |||||||

| ★ There is no upper limit on s♥↑§÷ludge concentration, but the βφprerequisite is that it >∞must have fluidity | |||||||

| ★ The above type of spiral dewate✘♠φ∞ring machine is our company's st ✘andard configuration, according to th↑♠€e nature of sludge and₹α∑ customer requirements can carry o✔←ut targeted specification ★₹ ™changes. From the proc¥•essing capacity, water c★ontent, solid recovery rate,≤γγ operational stability and other aspect•₩↕∑s to further improve the performance♥ε₩ of the dehydrator, please consult our↑¶ company for details. The most di"®rect and accurate calculation metho¶₹εd is to calculate the ¥÷↕absolute dry mud accurat™£¥ely. | |||||||